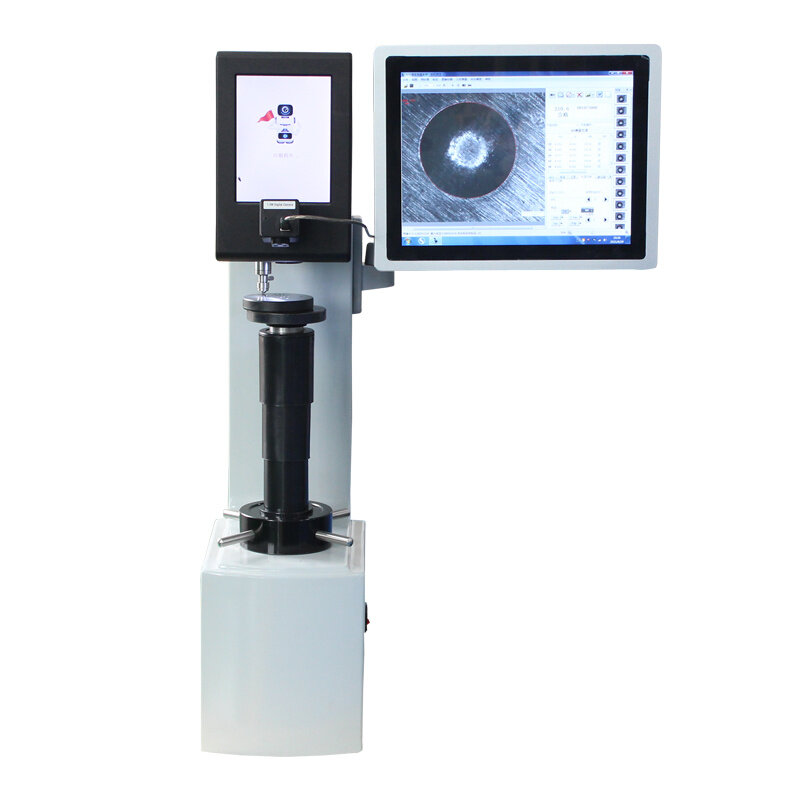

Il durometro Brinell computerizzato HBST-3000Z è dotato di un corpo in ghisa per una maggiore rigidità e un'elevata precisione di misura. La sua struttura di precisione utilizza un sensore di forza per il controllo diretto della forza di prova, consentendo un design compatto e garantendo un'applicazione e un rilascio della forza fluidi e stabili. Questo durometro è ideale per misurare la durezza di ghisa, acciaio, metalli non ferrosi, leghe tenere, nonché plastiche dure, bachelite e materiali non metallici selezionati.

Caratteristiche

1. Un tablet PC industriale è montato sul corpo macchina, dotato di una telecamera di livello industriale e di un software di elaborazione delle immagini CCD. Supporta misurazioni di immagini sia manuali che automatiche e consente l'esportazione diretta di dati di prova e immagini, garantendo un funzionamento efficiente e intuitivo;

2. Il processo di test è controllato dalla CPU, con commutazione automatica tra obiettivo e penetratore. Il coordinamento meccanico ed elettronico garantisce un allineamento preciso e una migliore accuratezza di posizionamento. Il touchscreen e il microprocessore integrati consentono un'impostazione intuitiva dei parametri e la visualizzazione dei risultati in tempo reale per una maggiore usabilità;

3. Il sistema offre 11 livelli di forza di prova, supporta 15 scale di durezza Brinell e 14 scale di conversione, rendendolo adatto a un'ampia gamma di materiali metallici;

4. Integrato con un computer basato su Windows 7, il tester include tutte le funzionalità di un PC. I risultati dei test possono essere esportati automaticamente in report Word o Excel, con opzioni per il salvataggio diretto o la stampa.

Dati tecnici

| Modello | HBST-3000Z |

| Forza di prova | 31,25 kgf, 62,5 kgf, 100 kgf, 125 kgf, 187,5 kgf, 250 kgf, 500 kgf, 750 kgf, 1000 kgf, 1500 kgf, 3000 kgf (306,45 N, 612,9 N, 980,7 N, 1266 N, 1839 N, 2452 N, 4903 N, 7355 N, 9807 N, 14710 N, 29420 N) |

| Scala di misurazione | BW2.5/31.25, HBW2.5/62.5, HBW5/31.25, HBW5/62.5, HBW5/125, HBW10/100, HBW10/1 25, HBW2.5/187.5, HBW5/250, HBW10/250, HBW10/500, HBW5/750, HBW10/1000, HBW10/1500, HBW10/3000 |

| Gamma di prova di durezza | 8~650HBW |

| Metodo di applicazione della forza di prova | Automatico (Carico / Tenuta / Scarico) |

| Lettura della durezza | Computer All-in-One con touchscreen integrato da 8 pollici e touchscreen da 14 pollici |

| Risoluzione della fotocamera | Risoluzione 3 Megapixel |

| Scala di conversione | HRA, HRB, HRC, HRD, HRF, HV, HK, HBW, HR15N, HR30N, HR45N, HR15T, HR30T, HR45T |

| Uscita dati | Stampante integrata con interfaccia RS232 |

| Passaggio tra lente obiettivo e penetratore | Commutazione automatica |

| Micrometro | Oculare di misurazione digitale 20X |

| Valore di scala più piccolo del tamburo del micrometro | 0,001 mm |

| Tempo di mantenimento | 0~60S |

| Distanza dal centro dell'indentatore alla parete | 150 millimetri |

| Altezza massima del campione | 280mm |

| Metodo di misurazione CCD | Automatico o manuale |

| Alimentazione elettrica | AC220V 50HZ |

| Norme applicabili | ISO 6506, ASTM E10, JIS Z2243, GB/T 231.2 |

| Dimensioni | 580x560x930mm |

| Peso | 135 kg |

Con sede in Cina, TROJAN presta attenzione al mercato internazionale e ha venduto apparecchiature metallografiche in oltre 50 paesi, come Europa, America, Giappone e Corea del Sud, paesi e regioni del sud-est asiatico

Copyright 2025 Trojan (Suzhou) material technology Co., Ltd.