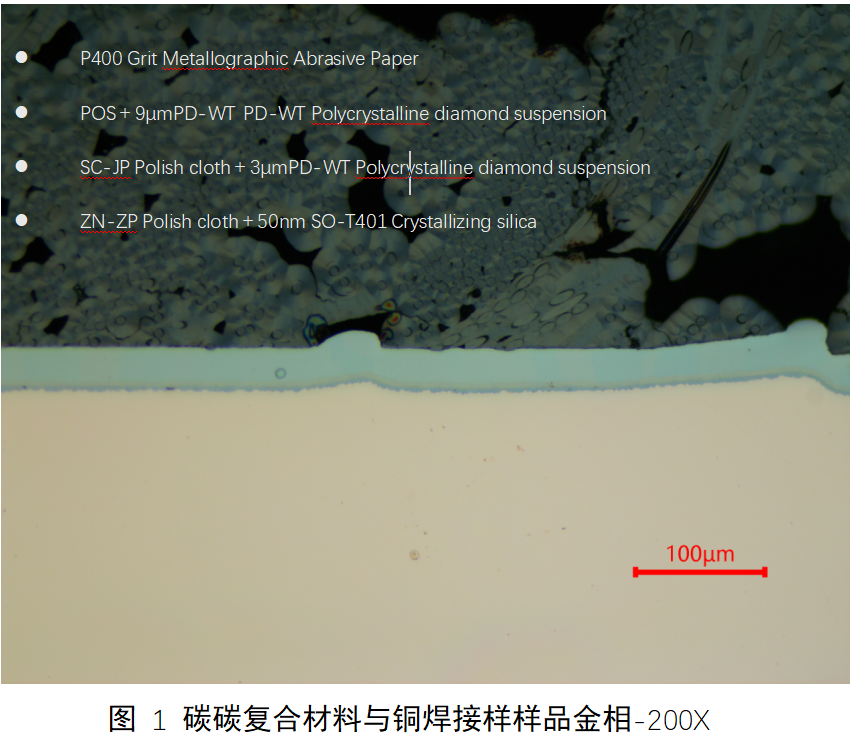

🔎 Amid the flames of spacecraft re-entering the atmosphere and in the circuit heart of new energy vehicles, the “tough guy and wise man” duo of carbon-carbon composite materials and copper welded joints are writing a material legend. As metallographic engineers, how do we decipher its microscopic codes? Next, we will take you on a journey to overcome the difficulties in preparing materials with different hardness and toughness in carbon-carbon composite material samples! For carbon-carbon composite materials and copper welding samples, to ensure the flatness of the prepared welding interface, it is recommended to use the POS plate four-step method for preparation. The following is the sample preparation process.

1⃣ : Use P400 metallographic sandpaper to grind the sample smooth;

2⃣ : Fine grinding is carried out using a POS grinding disc and 9μm PD-WT polycrystalline diamond suspension;

3⃣ : Polish with SC-JP polishing cloth and 3μm mPD-WT polycrystalline diamond polishing suspension;

4⃣ : Conduct the final polishing with ZN-ZP polishing cloth +SO-T401 50-nanometer silica polishing suspension.

#SteelMicrostructure #MaterialScience #Metallography #SteelSamples #MicrostructureAnalysis #SteelPrep #MaterialTechnician #SamplePreparation #Microscopy #MetallurgicalTesting #SteelAlloys #SteelPolishing #MicrostructureTesting #MetallographyLab #MaterialAnalysis #SteelQuality #MicroscopicView #MetallurgicalEngineering #LabTechLife #MaterialsTesting #StructuralAnalysis #metallurgymonday #crosssection #coldmounting