7MHVS-1000A 7MHVS-1000A Digital Micro Hardness Tester Mainly used for micro-Vickers hardness measurement of various metals and some non-metallic materials. Capable of measuring the hardness of various parts (machined parts, forgings, cast iron, cast steel parts, etc.), non-ferrous metals, heat post-treated parts, various tiny and thin parts, glass, ceramics, agate, gemstones, etc.,It is also applicable to the measurement of effective depth of carbonization, effective depth of quenching and hardening layer, coating, surface coating and heat affected parts of welding parts. It can also be used for the observation of the internal metallographic organization of various metal parts and the collect, display and output of images. Especially suitable for measuring the hardness gradient distribution curve of the workpiece, the surface hardness of gears after heat treatment and the depth of effective hardened layer.

This product adopts a unique and precise design in mechanics, optics and light source, enables clearer indentation imaging and more accurate measurement

. 7MHVS-1000A adopts the new touch screen display, the operation interface adopts the menu structure. The hardness scale HV or HK and the tested hardness value can be selected on the operation panel. It can convert various hardness values.

The machine is equipped with a 10x digital display measuring microscope and a 40x objective lens both of which can participate in the measurement, making the measurement range larger and the application wider.

Using touch screen, the operation is more intuitive and clearer, able to display the test method, test force, indentation length, hardness value, test force holding time, number of measurements, date, time, hardness conversion value, etc. on the screen. It has functions such as conversion scale, storage, printing, etc. and has a threaded interface for connecting a digital camera and CCD camera, which is convenient for optional computer and hardness analysis and measurement software.

| Model | 7MHVS-1000A |

| Testing force | 10gf、25gf、50gf、100gf、200gf、300gf、500gf、1kgf

0.098N、0.245N、0.49N、0.98N、1.96N、2.94N、4.9N、9.8N |

| Convert Scales | HRA、HRB、HRC、HRD、HRF、HV、HK、HBW、HBS、HR15N、HR30N、HR45N、HR15T、HR30T、HR45T |

| Min. Measuring unit | 0.025μm |

| Testing Mode | HV/HK |

| Testing range | 5~3000HV |

| Test Force Application Method | Automatic(Loading、Dwelling、Unloading) |

| Turret Method | Automatic |

| Objective | 10X、40X |

| Eyepiece | 10X |

| Total magnification | 100X (observation) 400X (measurement) |

| Test force dwell time | 1~60s |

| X-Y table size | 100*100mm |

| X-Y Test Table Max. Movement | 25*25mm |

| Data output | Touch screen readout with built-in printer |

| Max. Sample Height | 110mm |

| The Distance From the Center of the Indenter To the Inner Wall | 110mm |

| Power Supply | AC220V±5%,50~60Hz |

| Execute Standard | ISO 6507,ASTM E384,JIS Z2244,GB/T 4340.2 |

| Dimension | 405*290*480mm |

| Weight | About 40kg |

Introduction to the function of each component:

Hardness meter control panel:The operation interface adopts humanized format, with Chinese and English switching function, suitable for multinational personnel to operate. Menu function classification is clear and detailed, and the light brightness, menu selection and objective lens selection all have memory functions.

Light source components:Use halogen lamp for clearer imaging.

Advantages:

01.It has the functions of data storage query and average calculation, using a three-point card position for dotting positioning, more accurate and can ensure the repeated dotting position does not deviate.

The supporting shrapnel is made of imported special customized materials with high toughness, high fatigue resistance and not easy to deform.

02.The operation interface adopts 7-inch LCD touch screen, can switch between Chinese and English directly, suitable for multinational personnel to operate.Menu function classification is clear and detailed, and the light brightness, menu selection and objective lens selection all have memory functions.

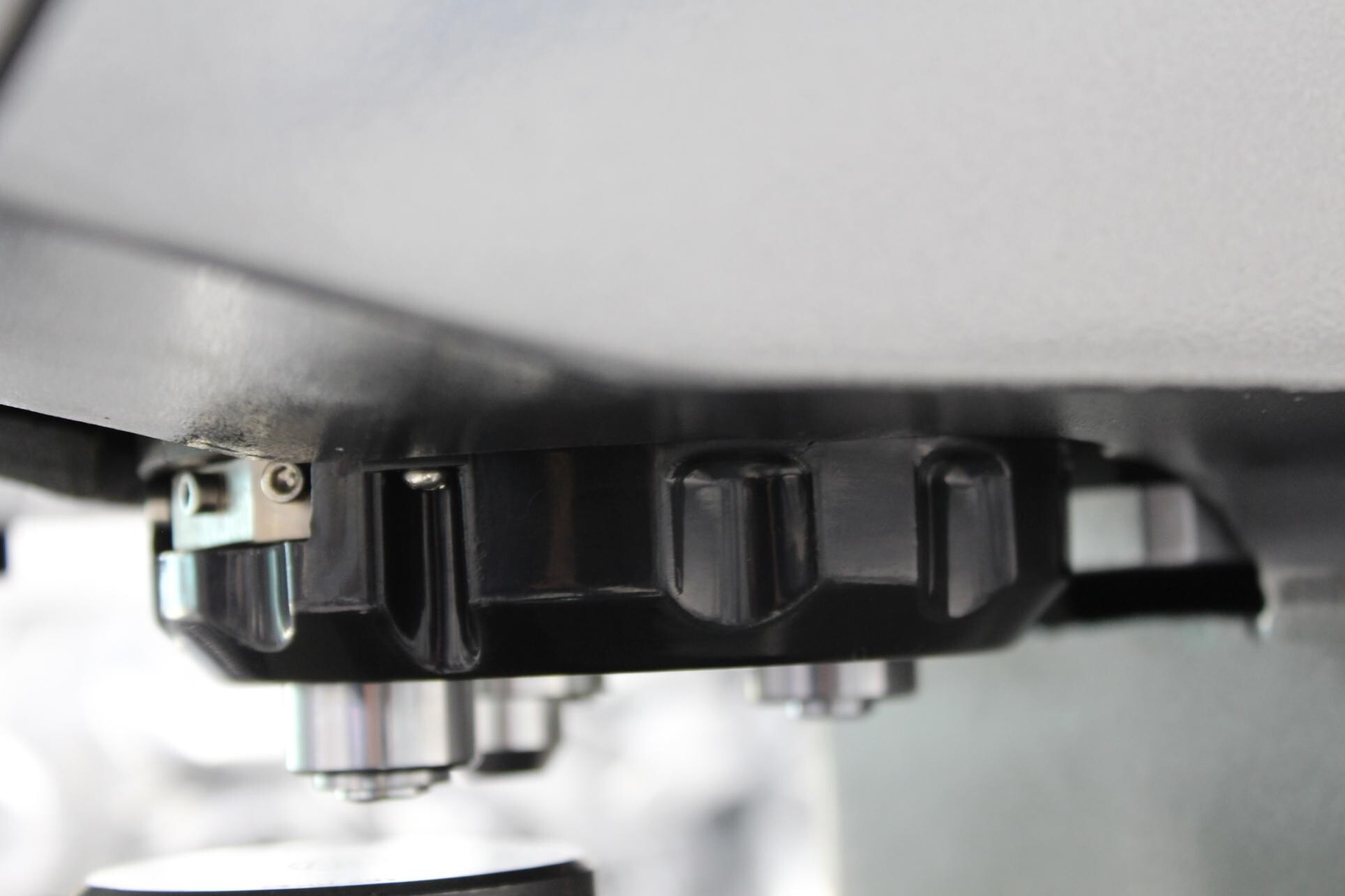

03.The table lifting adopts worm gear operating system, enabling a more stable transmission.

04.Use quality micrometers for clearer imaging and more accurate measurements.

05.Equipped with flat mouth support table and filament support table to fix different shape workpieces.

06.Genuine hardness measurement software is optional.

Packing list:

| Name | Specification | Unit | Quantity | Remark |

| Shaft for Standard Weight | Pcs | 1 | ||

| Cross Test Bench | Set | 1 | ||

| Flat Clamp Table | Set | 1 | ||

| Screwdriver | Pcs | 2 | ||

| Spirit Level | Pcs | 1 | ||

| Micro Vickers Hardness Block | high block, low block | Pcs | 2 | 1 each |

| Power Cable | Pcs | 1 | ||

| Manual | Pcs | 1 | ||

| Certificate of Qualification | Pcs | 1 | ||

| Standard Weight | Set | 6 | ||

| Sheet Clamp Table | Set | 1 | ||

| Adjusting Screw | Pcs | 4 | ||

| Micrometer Eyepiece | Set | 1 | ||

| Spare Fuse | 2A | Pcs | 2 |

Based in China, TROJAN pays attention to the international market, and has sold metallographic equipment to more than 50 countries, such as Europe, America, Japan and South Korea, Southeast Asia countries and regions

Copyright 2025 Trojan (Suzhou) material technology Co., Ltd.