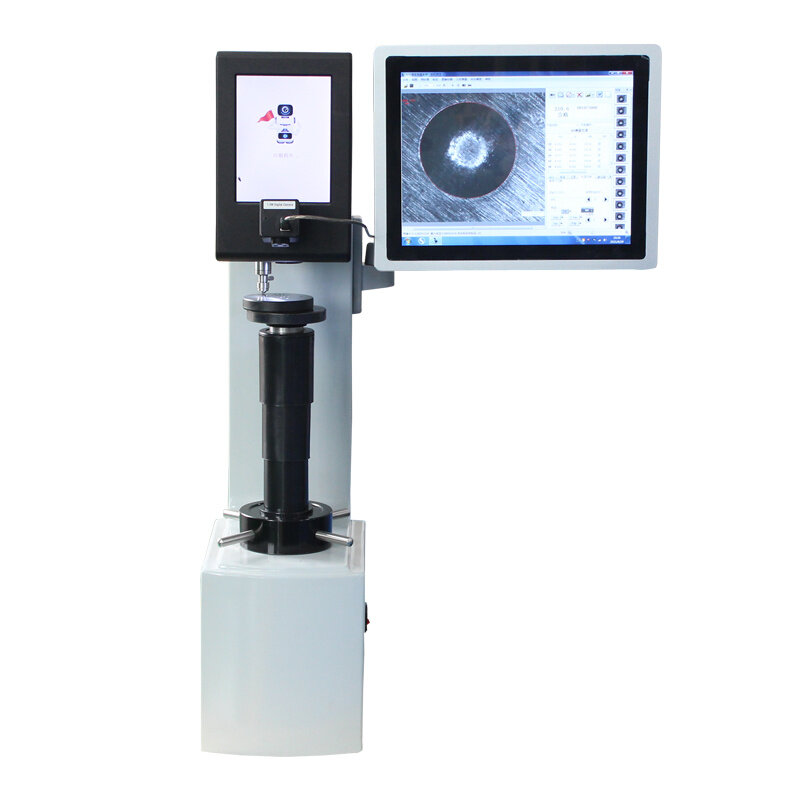

The HBST-3000Z Computerized Brinell Hardness Tester features a cast-iron body for enhanced rigidity and high measurement accuracy. Its precision-engineered structure uses a force sensor for direct control of the test force, enabling a compact design and ensuring smooth, stable application and release of force. This tester is ideal for measuring the hardness of cast iron, steel non-ferrous metals, soft alloys, as well as hard plastics, bakelite, and selected non-metallic materials.

Features

1. An industrial tablet PC is mounted on the machine body, equipped with an industrial-grade camera and CCD image processing software. It supports both manual and automatic image measurements, and allows direct export of test data and images, ensuring efficient and user-friendly operation;

2. The testing process is CPU-controlled, with automatic switching between the objective lens and indenter. Mechanical and electronic coordination ensures precise alignment and improved positioning accuracy. The built-in touchscreen and microprocessor provide intuitive parameter settings and real-time result display for enhanced usability;

3. The system offers 11 levels of test force, supports 15 Brinell hardness scales and 14 conversion scales, making it suitable for awide range of metallic materials;

4. Integrated with a Windows 7-based computer, the tester includes full PC functionality. Test results can be automatically exported into Word or Excel reports, with options for direct saving or printing.

Technical Data

| Model | HBST-3000Z |

| Testing Force | 31.25kgf, 62.5kgf, 100kgf, 125kgf, 187.5kgf, 250kgf, 500kgf, 750kgf, 1000kgf, 1500kgf, 3000kgf(306.45N, 612.9N, 980.7N, 1266N, 1839N, 2452N, 4903N, 7355N, 9807N, 14710N, 29420N) |

| Measurement Scale | BW2.5/31.25, HBW2.5/62.5, HBW5/31.25, HBW5/62.5, HBW5/125, HBW10/100, HBW10/1 25, HBW2.5/187.5, HBW5/250, HBW10/250, HBW10/500, HBW5/750, HBW10/1000, HBW10/1500, HBW10/3000 |

| Hardness Testing Range | 8~650HBW |

| Method of Applying Test Force | Automatic (Loading / Holding / Unloading) |

| Hardness Reading | 8-inch Integrated Touchscreen, 14-inch Touchscreen All in-One Computer |

| Camera Resolution | 3 Megapixel Resolution |

| Conversion Scale | HRA, HRB, HRC, HRD, HRF, HV, HK, HBW, HR15N, HR30N, HR45N, HR15T, HR30T, HR45T |

| Data Output | Integrated Printer with RS232 Interface |

| Switching Between Objective Lens and Indenter | Automatic Switching |

| Micrometer | 20X Digital Measuring Eyepiece |

| Smallest Scale Value of the Micrometer Drum | 0.001mm |

| Holding Time | 0~60S |

| Distance from the Center of the Indenter to Wall | 150mm |

| Maximum Sample Height | 280mm |

| CCD Measurement Method | Automatic or Manual |

| Power Supply | AC220V 50HZ |

| Applicable Standards | ISO 6506, ASTM E10, JIS Z2243, GB/T 231.2 |

| Dimensions | 580x560x930mm |

| Weight | 135kg |

Based in China, TROJAN pays attention to the international market, and has sold metallographic equipment to more than 50 countries, such as Europe, America, Japan and South Korea, Southeast Asia countries and regions

Copyright 2025 Trojan (Suzhou) material technology Co., Ltd.