_副本-scaled.jpg)

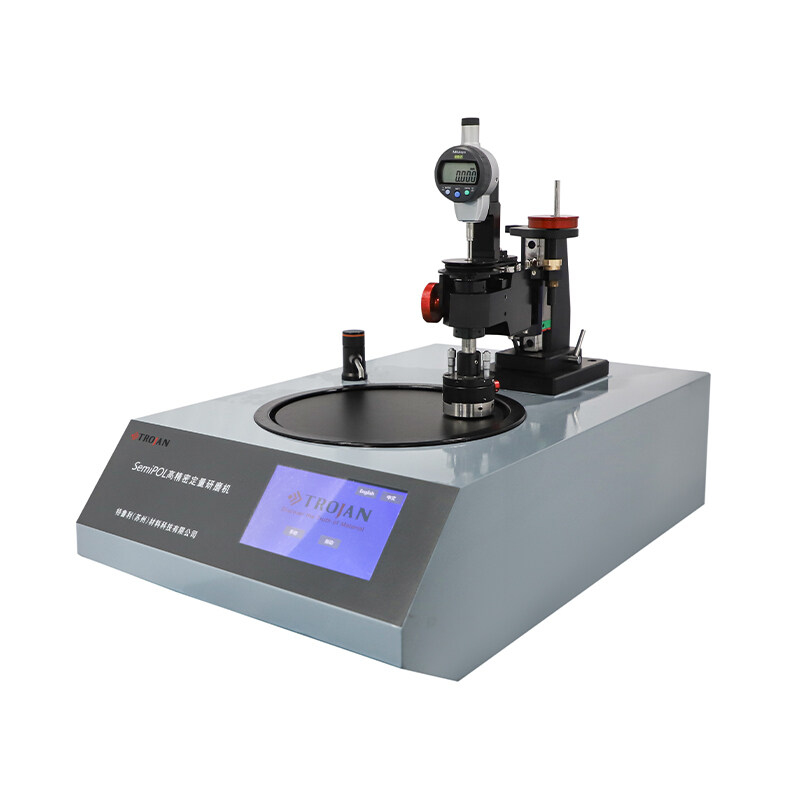

SemiPOL is designed for precise grinding and polishing of a wide range of materials, including integrated circuits, semiconductor wafers, optical components, optical fibers, petrographic structures, and precision metal parts. It delivers micron-level accuracy, making it ideal for preparing samples for microscopic analysis (SEM, FIB, TEM, etc.). Key applications include parallel grinding, polishing, quantitative thinning, and continuous slicing. With a variety of accessories and fixtures, SemiPOL simplifies the grinding and polishing of complex and custom-shaped components.

1、7-inch LCD touch screen panel, displays the removal in real time, the interface is simple and easy to understand, the operation is convenient.

2、16 sets of process parameters can be saved and edited.

3、Size:8″(Ф203mm) or 10″(Ф254mm), flatness < 2µm.

4、Sample rotation: 0 ~50rpm, disc rotation: 0 ~350rpm, both are continuously viable speed, both can be forward/reverse.

5、Maximum removal: 10mm, resolution: 1um, stable accuracy: ±2µm.

6、The servo drive motor (750 W) provides constant high torgue output stably and permanently with a long service life.

7、Built-in automatic temperature sensing cooling fan to reduce failure rate and increase service life.

8、Large diameter side discharge water outlet, not easy to clog and drain quickly.

9、Pluggable faucet, convenient for cleaning and maintenance of the disk.

| Model | SemiPOL | |

| Working disc | Diameter | 8-10 inch(203/254mm) |

| Speed | 0-350rpm,continuously viable speed | |

| Direction | CW/CCW | |

| Power | 750W | |

| factory inspection | Flatness < 2µm | |

| Sample holder | Speed | 0-50rpm,continuously viable speed |

| Direction | CW/CCW | |

| Rotation | Yes,with adjustable amplitude | |

| Oscillation | Yes,amplitude and speed are adjustable | |

| factory inspection | Perpendicularity to the disk <2µm; parallelism <2µm | |

| Maximum removal capacity | 10mm | |

| Electricity | Power supply | 220VAC |

| Panel | 7-inch touch screen | |

| Dimension | WxDxH | 700x430x580mm |

| Weight | 57kg | |

SemiPOL Accessories

1. Working Wheel

Ordering Information:

25.03.072 8″(200mm)

25.03.082 10″(250mm)

2. Flat Pasting Fixture

Ordering Information:25.03.600 46-1000

3. Tear-drop Fixture

Ordering Information:25.03.610 46-1001

4. Multifunctional Fixture

Ordering Information:25.03.620 46-1002

5. Side Sticking Fixture

Ordering Information:

25.03.630 46-1003

25.03.635 46-1005

6. Side Clamping Fixture

Ordering Information:25.03.640 46-1004

7. Flat Suction Fixture

Ordering Information:25.03.605 46-1006

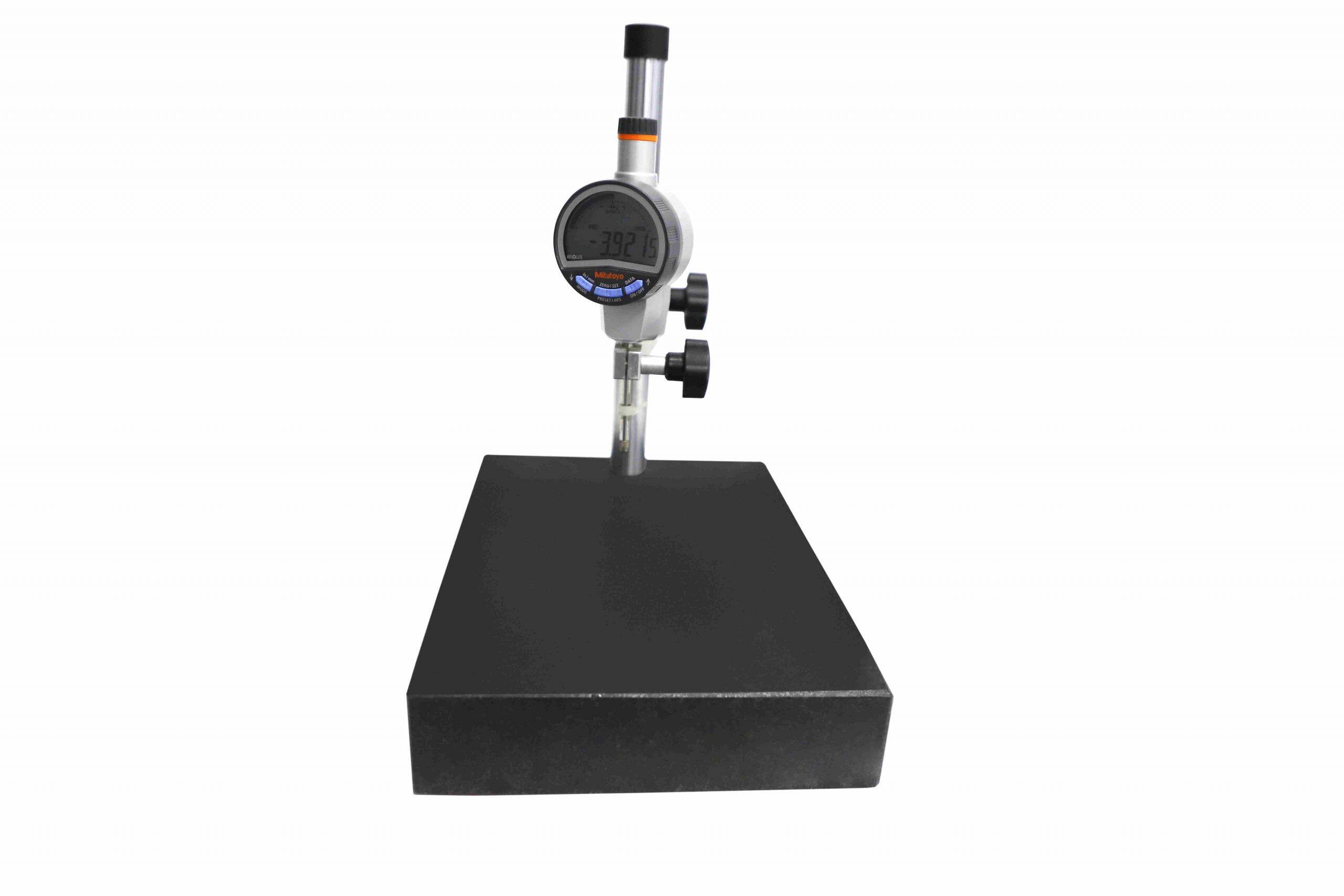

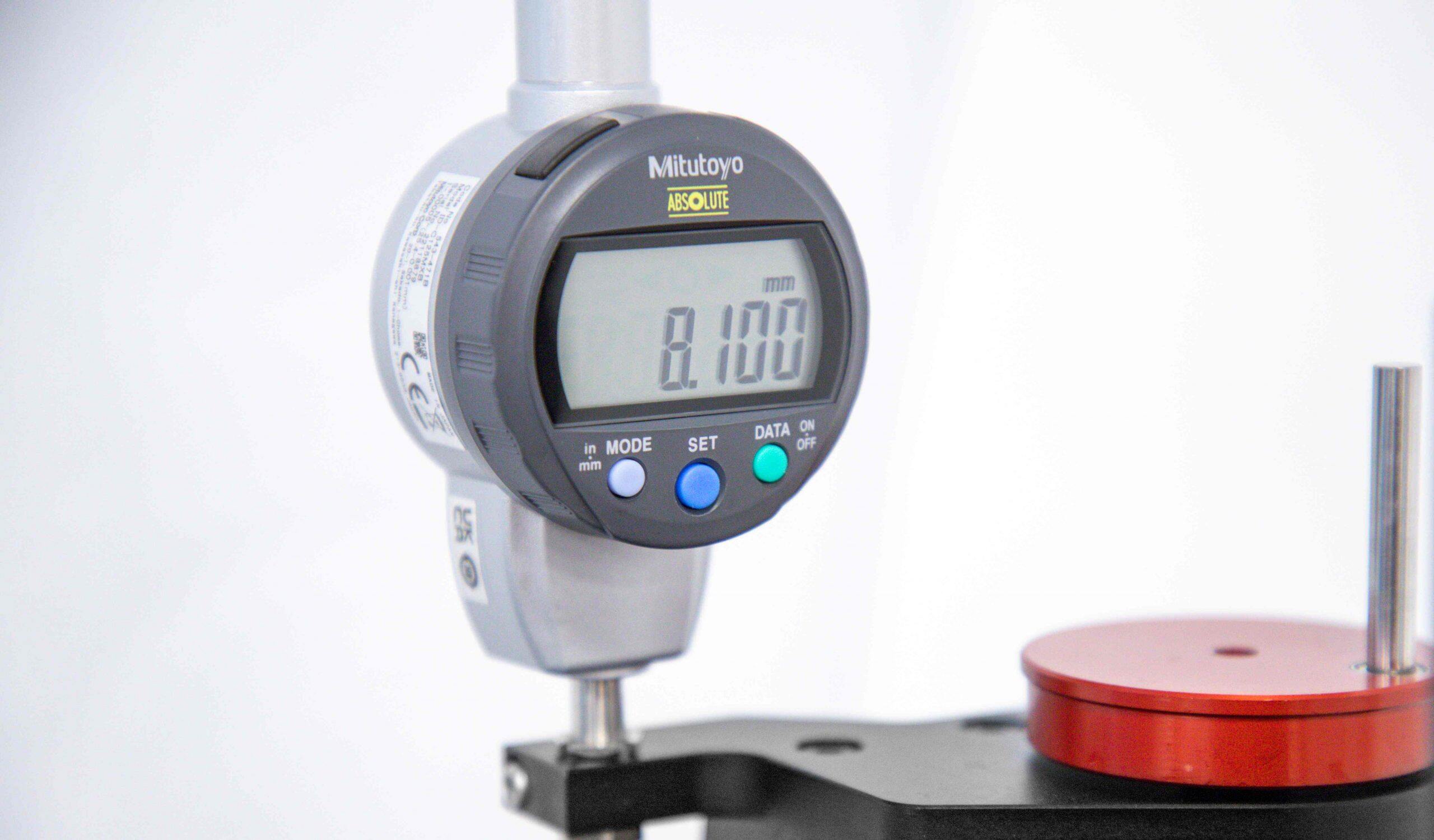

8. Digital Height Gauge

Ordering Information:25.03.650 46-2000

Based in China, TROJAN pays attention to the international market, and has sold metallographic equipment to more than 50 countries, such as Europe, America, Japan and South Korea, Southeast Asia countries and regions

Copyright 2025 Trojan (Suzhou) material technology Co., Ltd.