As the core acoustic component of mobile devices, smartphone speakers rely on precision micro-welding and assembly to deliver Hi-Fi sound in ultra-slim designs. Their performance & lifespan depend entirely on coil weld quality, magnetic coating uniformity, and component fit accuracy. Check out our metallographic sample prep workflow for crystal-clear micrographs: 1️⃣ P180 SiC disc → […]

In the industrial kingdom woven by steel and iron, welds never seek the spotlight, yet they hold the core power to prop up countless pieces of equipment and projects, truly deserving the name of invisible “life veins”. From the steel structures of bridges spanning rivers, to the aero-engines soaring through the sky; from the shells […]

As high-performance heat transfer components, finned tubes boost heat exchange area dramatically by adding fins to the base tube surface. This enables more compact, efficient heat transfer—making them indispensable across key industrial sectors. The welding quality between fins and base tube is non-negotiable for equipment safety & lifespan. Secure metallurgical bonding is a must to […]

In the manufacturing of drill bits and cutting tools, metallographic inspection of metal powders prior to sintering serves as the fundamental guarantee for quality control. By preparing and observing raw powder samples, the internal microstructure can be directly evaluated—including the degree of pre-alloying, morphology of primary carbides, and purity—thus predicting the uniformity of the sintered […]

When it comes to gypsum rock, don’t just think of construction gypsum boards! This sedimentary rock formed from calcium sulfate minerals has plenty of hidden talents. Its formation dates back to ancient oceans or lakes. As water evaporated, calcium sulfate crystals gradually precipitated and compacted, eventually forming the gypsum rock we see today. It is […]

Thermal spray coating is known as the “protective armor” for industrial components, widely used in machinery, aerospace, energy and other fields. It not only provides wear-resistant protection for easily worn shafts and blades, but also builds a corrosion-resistant barrier for pipelines and containers in corrosive environments. Additionally, it can realize functions such as heat insulation […]

New energy power battery modules impose extremely high requirements on the reliability of electrical connections. Aluminum busbars, thanks to their excellent electrical conductivity and lightweight characteristics, have become key connecting components inside the modules. Laser welding technology, with its advantages of high energy density and precise heat input, effectively resolves process challenges such as oxidation […]

Aluminum, a lightweight metal with balanced properties, is limited in high-end applications by its inherent insufficient strength and heat resistance. Aluminum matrix composites achieve performance breakthroughs by incorporating nano-scale or micro-scale reinforcement particles, while retaining aluminum’s excellent characteristics. Through interactions with dislocations (such as hindrance and surrounding) and load transfer effects, reinforcement particles effectively impede […]

Objective: Grind and polish the chip end face to a mirror finish, ensuring end face perpendicularity and no edge chipping. Key Challenges: Silicon-based chips are brittle, small in size, and difficult to fix during sample preparation. Material: Silicon-based chip Equipment & Accessories Equipment: Semipol high-precision grinding and polishing machine Accessories: Thin-sheet sample mounting fixture Consumables […]

Preparing high-temperature oxidation-resistant ceramic coatings on niobium and niobium alloy substrates is a key surface technology to extend their excellent high-temperature strength for applications in oxygen-containing environments. The core challenges in this field lie in resolving the enormous thermal stress caused by the mismatch in thermal expansion coefficients between metals and ceramics, as well as […]

316 powder metallurgy (PM) stainless steel, leveraging its advantages of corrosion resistance, high strength, and near-net shaping, has been widely applied in scenarios such as automotive engine valve cores, medical device implants, chemical corrosion-resistant valves, offshore platform fasteners, and electronic equipment structural components. The core purpose of its sample preparation is not only to present […]

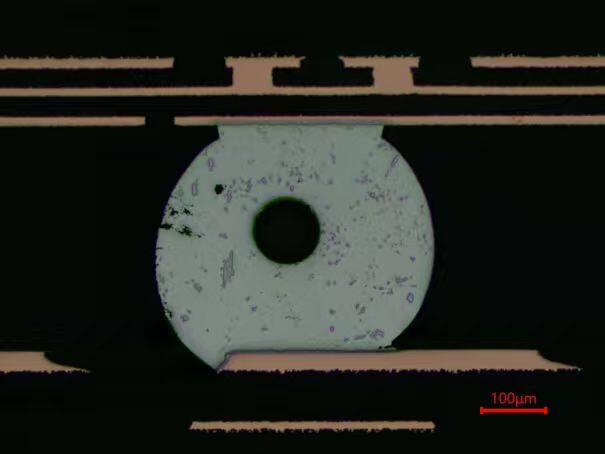

Chip solder balls are small spherical beads made of pure tin or tin alloys. They are used to provide electrical connection and mechanical support between chip packaging and printed circuit boards (PCBs), as well as connections between stacked packages in multi-chip modules (MCMs). In Ball Grid Array (BGA) packaging, solder balls resolve the conflict between […]

Cermet, also known as ceramic matrix composite, is a multiphase system composed of metals or alloys and one or more ceramic phases. This type of material integrates the excellent toughness and thermal conductivity of the metal phase with the high hardness, wear resistance and heat resistance of the ceramic phase, thus combining the advantages of […]

As the core carrier of electronic manufacturing, the internal structural quality of PCBs directly determines the reliability of end products. Metallographic section testing is the most robust “quality perspective tool” in the PCB industry, unlocking the “hidden truth” of circuit boards step by step—from sampling, mounting, grinding, polishing to microscopic observation. Whether it is […]

In the field of materials science, martensitic stainless steel occupies a unique position due to its heat-treatable strengthening property, with 431 steel (Chinese grade: 1Cr17Ni2) being a typical representative. Its performance stems from precise alloy design: 💠 Carbon content (≤0.20%), as interstitial atoms, is the core of martensitic transformation. Quenching after austenitization forms a supersaturated […]

As electronic products continue to evolve towards miniaturization and high-density integration, ball grid array (BGA) packaging has become the core packaging form for devices such as smartphones and aerospace systems due to its ability to achieve high I/O pin density connections. Although the solder joints between BGA and printed circuit boards (PCBs) are of tiny […]

Copper resistors are by no means simple “conductive components”—their core value stems from their resistance-temperature characteristics and low resistivity advantages, which together underpin their applications across multiple fields. They serve three core functions: – **Temperature sensing**: Converting temperature into electrical signals; – **Energy transmission**: Acting as “conductive bridges” to reduce circuit losses; – **Circuit […]

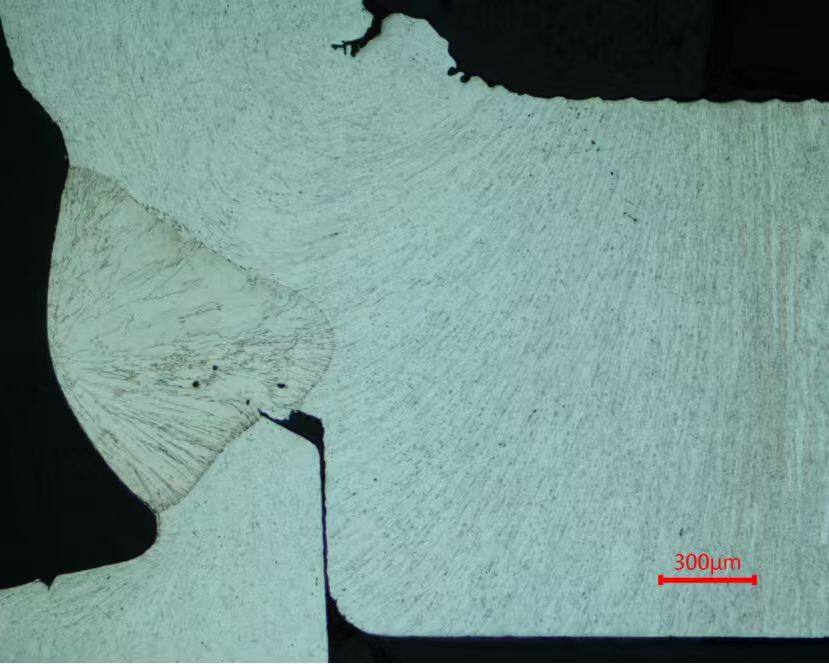

The aluminum alloy welding samples exhibited the phenomenon of a rainbow film after being exposed to corrosion and cleaning. The pictures show the aluminum alloy welding samples with the rainbow film, and the surface of the sample re-prepared after vacuum impregnation to fill the pores. When there are gaps between the sample and the resin […]

Based in China, TROJAN pays attention to the international market, and has sold metallographic equipment to more than 50 countries, such as Europe, America, Japan and South Korea, Southeast Asia countries and regions

Copyright 2025 Trojan (Suzhou) material technology Co., Ltd.